Slips

Ramey Martin Drill Pipe, Drill Collar, Casing, and Tubing Slips are used when adding or removing joints from the drill string. Our slips designed to meet or exceed API standards and proudly made in the USA.

-

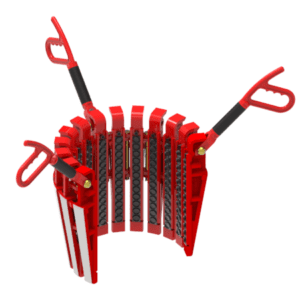

C-1 Slips (6)

The Ramey Martin C-1 Drill Collar Slip has a multi-segment design that allows it to hinge so that it fits all drill collars within the slips size range. The slip segments are heat-treated for strength and wear resistance. All RMET C-1 slips are machined with a taper of 4" taper per foot (TPF) on the diameter and manufactured in accordance with API 7K specifications. It is provided with safety flex handles as a standard option, but is also available with steel handles as well. -

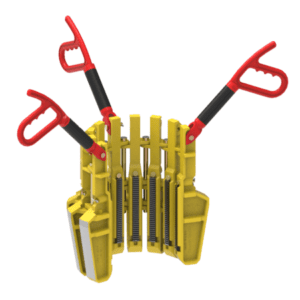

CMS Slips (24)

Ramey Martin “CMS” Casing Slips have a multi-segment design which gives a full wrap-around to help prevent damage to casing. By adding or subtracting segments & inserts, the slip can accommodate 6 5/8” - 30” O.D. casing. The segments are made of alloy steel and are heat-treated for strength and wear resistance. CMS-XL slip has an API taper of 4” per foot on the diameter while the CMS-3 slip has an API taper of 3” per foot on the diameter. For added safety, the Ramey Martin “CMS” Casing Slip is also provided with safety flex handles as a standard option with steel handles available upon request. -

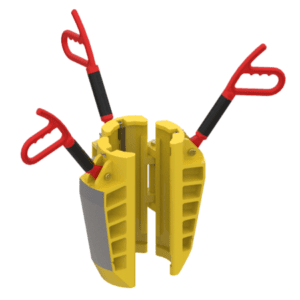

DCS Slips (12)

Ramey Martin "DCS" Type Drill Collar Slips have a multi-segment design to give a full wrap-around to insure a proper slip setting. The slips are made of alloy steel and heat-treated for strength and wear resistance. It is load rated and has an API taper of 4"/ft on the diameter. For added safety, the Ramey Martin "DCS" Type Drill Collar Slip is also provided with safety flex handles as a standard option. Steel handles are available upon request. -

DU Slips (6)

The Ramey Martin DU Rotary Slips are designed for long trouble-free service. They are made of alloy steel and heat-treated for strength and resistance to wear. The slip is machined for use in API tapered bowls with a 4" taper per foot(TPF) on the diameter. The DU Regular has a 12" gripping service for use in shallow wells while the DU Long has a 16" gripping surface for deeper wells and heavier drill strings. All Ramey Martin DU Rotary Slips are load rated and manufactured to meet API 7K requirements. -

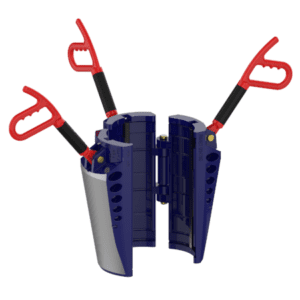

SD Rotary Slips (4)

Ramey Martin "SDML" and "SDXL" Slips are made of alloy steel and heat-treated for strength and wear-resistance. They are machined for use in API standard bowls. We have designed our slip to operate without load rings and still maintain 100% insert support, eliminating the need for beveled inserts. Complete inspections can be performed without the worry of load ring bolts breaking or seizing after use. The use of roll pin retainers and larger knock out holes beneath the hinge pins saves time during disassembly. All Ramey Martin "SD" Slips are load rated and have an API taper of 4" per foot (TPF) on the diameter. For added safety, Ramey Martin "SDML" and "SDXL" Slips are provided with safety flex handles as a standard option. Steel handles for available upon request. -

TS-100 (3)

-

Woolley Drill Collar Slips (6)

The Ramey Martin Type "A" Drill Collar Slip has a multi-segment design that allows it to hinge so that it fits all drill collars within the slips size range. The slip segments are heat-treated for strength and wear resistance. All RMET Type "A" slips are machined with a taper of 4" taper per foot (TPF) on the diameter and manufactured in accordance with API 7K specifications. It is provided with safety flex handles as a standard option, but is also available with steel handles as well. -

Woolley Rotary Slips (2)

-

XD Slip (1)

The Ramey Martin 7 5/8" XD 750 Ton Rotary Slip can handle a variety of tubulars. It is designed in accordance with API Specification 7K, 6th Edition. The slip has a 4" taper per foot (TPF) for use in a standard #3 Insert Bowl and has a minimum operating temperature of -4 degrees F. Special recessed insert slots along with matching inserts ensures proper installation of the directional inserts. The XD-750 has a size range of 5" to 7 5/8" with a gripping length of 16". It has been heat-treated for strength and wear. The slip comes standard with safety flex handles and steel handles available upon request.